What Exactly Is Noise-Induced Hearing Loss?

Noise-induced hearing loss (NIHL) isn’t just ringing in your ears after a loud concert. It’s a slow, silent thief that steals your hearing over time - especially if you work in construction, manufacturing, mining, or agriculture. Unlike an ear infection or a sudden pop, NIHL doesn’t hurt. You don’t notice it until you’re struggling to hear your kid talk over the TV, or you keep asking coworkers to repeat themselves. By then, it’s permanent.

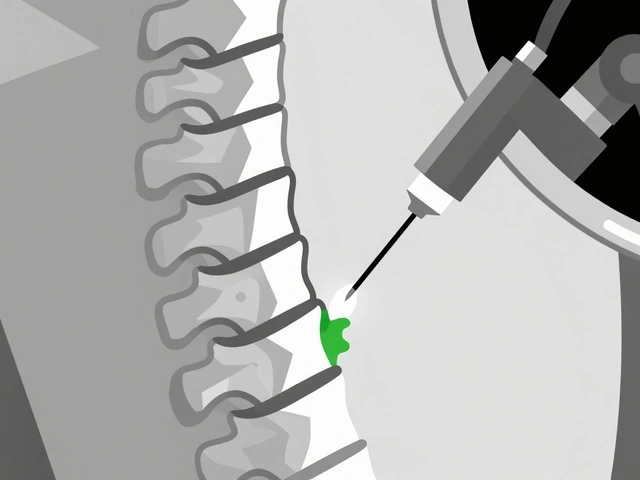

The damage happens deep inside your inner ear, where tiny hair cells pick up sound vibrations and send signals to your brain. These cells don’t grow back. Once they’re gone, you can’t get them back. That’s why NIHL is called a permanent injury - even if you stop the noise, the damage stays.

How Loud Is Too Loud?

Many people think if it’s not painful, it’s safe. That’s wrong. The real danger starts at 85 decibels (dBA) - the sound of heavy city traffic or a lawnmower. If you’re exposed to that level for eight hours straight, your risk of hearing loss begins to climb. And it doesn’t just add up - it multiplies.

Here’s the math: for every 3 dB increase, your safe exposure time cuts in half. So at 88 dBA, you’ve got only 4 hours. At 91 dBA, just 2 hours. At 94 dBA? Only 1 hour. A jackhammer runs at 130 dBA - you can damage your hearing in under a minute.

Regulations vary. OSHA lets you work up to 90 dBA for 8 hours. But NIOSH, the agency that actually studies this stuff, says 85 dBA is the real line. The European Union is even stricter - they act at 80 dBA. Why the difference? Because OSHA’s rules are based on what’s feasible for industry. NIOSH’s are based on what actually protects your hearing.

Who’s at Risk?

You don’t have to be in a factory to be at risk. According to CDC data, these industries have the highest exposure rates:

- Construction - 22% of workers exposed to dangerous noise

- Manufacturing - 19%

- Mining - 17%

- Agriculture - 15%

But it’s not just the machines. Think about the tools: impact wrenches, saws, compressors, pneumatic drills. Even a chainsaw hits 110 dBA. And in warehouses, forklifts, conveyor belts, and packing lines create constant background noise that adds up over a 10-hour shift.

Here’s the kicker: 22 million U.S. workers are exposed to hazardous noise every year. And yet, only about half of companies in high-risk industries actually follow the basic hearing conservation rules.

Why Hearing Protection Often Fails

Most workplaces hand out foam earplugs like candy. But here’s the problem: 75% of workers insert them wrong. You’ve got to roll them into a thin cylinder, pull your ear up and back, then shove them in deep. Most people just stuff them in like cotton balls. Result? Instead of 30 dB of protection, you get 15 - maybe less.

And then there’s comfort. Workers remove them because they can’t hear warnings, alarms, or coworkers. One construction worker on Reddit said his foam plugs hurt after two hours, so he took them out. He’s been working for 15 years. He can’t hear his wife’s voice clearly anymore.

Custom-molded earplugs work better. They’re shaped to your ear, last years, and block noise without muffling speech. But they cost more. And if management doesn’t invest in them, workers won’t use them.

Real-world data shows only 38% of workers in noisy jobs wear protection all day. The top reasons? Discomfort (67%), communication issues (58%), and thinking it’s not necessary (42%).

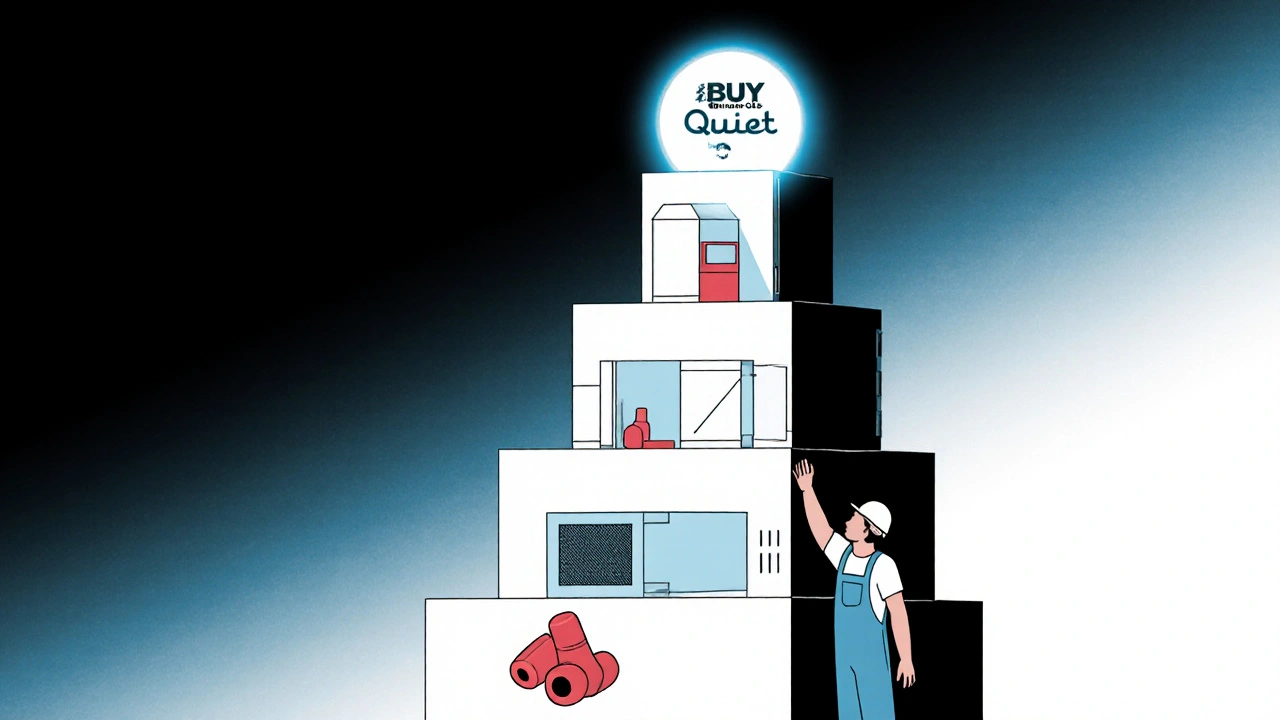

The Best Way to Stop Hearing Loss - Before It Starts

There’s a proven way to stop NIHL before it starts. It’s called the hierarchy of controls. And it goes like this:

- Eliminate the noise - get quieter equipment. This is the gold standard. NIOSH’s ‘Buy-Quiet’ program lists over 1,200 tools that are 3-15 dB quieter than standard models. A drill that runs at 88 dBA instead of 100 dBA cuts your exposure risk by more than half.

- Substitute - swap noisy processes for quieter ones. Use hydraulic presses instead of impact tools. Use welding instead of riveting.

- Engineering controls - put barriers around machines, enclose noisy areas, install sound-absorbing panels. In one mining case, noise dropped from 98 dBA to 82 dBA after adding enclosures. Workers reported less fatigue and better focus.

- Administrative controls - rotate workers, limit time in noisy zones, schedule loud tasks for low-traffic hours. But this only works if it’s enforced. Studies show effectiveness varies wildly - from 25% to 75% - depending on how well it’s managed.

- Hearing protection - this is your last line of defense. It’s the least reliable because it depends on human behavior. If you don’t wear it, or wear it wrong, it doesn’t work.

Too many companies skip straight to step five. They buy cheap earplugs and call it a day. That’s not a prevention plan. That’s a liability.

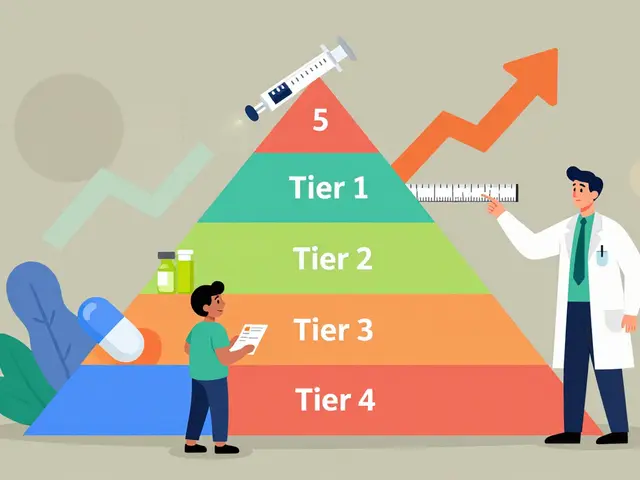

What a Real Hearing Conservation Program Looks Like

Effective programs don’t just hand out earplugs. They follow a 5-step system backed by NIOSH and OSHA:

- Noise monitoring - measure noise levels with a calibrated sound meter. Annual checks are mandatory. Use Type 2 meters, not phone apps (even NIOSH’s app is only for screening).

- Engineering fixes - if noise hits 90 dBA, you must reduce it. Not just with earplugs. With enclosures, dampeners, or quieter machines.

- Proper hearing protection - offer multiple types: foam, silicone, custom. And don’t just hand them out. Train workers on how to use them. Real Ear Attenuation at Threshold (REAT) testing shows if the plug actually works in their ear.

- Audiometric testing - annual hearing tests at 500, 1000, 2000, 3000, 4000, and 6000 Hz. A shift of 10 dB or more at 2000-4000 Hz over baseline means hearing loss has started. Catch it early, and you can stop it.

- Training - workers need 10-15 minutes of one-on-one instruction on how to insert earplugs. Group videos don’t cut it. Studies show training improves short-term use by 30-50%.

Companies that do this right spend $150-$300 per employee per year. But they save $5.50 for every $1 spent - through fewer workers’ comp claims, lower turnover, and better productivity.

The Hidden Cost of Ignoring Hearing Loss

NIHL isn’t just about hearing. It’s about safety. Workers with hearing loss miss alarms, warnings, and verbal cues. They’re more likely to have accidents. In one study, workers with untreated hearing loss were 40% more likely to suffer workplace injuries.

And the financial toll? In 2022, there were 19,300 reported cases of occupational hearing loss in the U.S. Each claim cost an average of $14,700. That’s nearly $284 million in workers’ comp payouts in one year alone.

And it’s getting worse. California now requires employers to try engineering controls before relying on hearing protection. The EU lowered its action level to 80 dBA. NIOSH is pushing for 80 dBA as the new U.S. limit by 2025.

Companies that wait are playing Russian roulette with their workers’ health - and their own wallets.

What You Can Do - Even If You’re Not a Boss

If you work in a noisy job:

- Ask for better hearing protection. Not just foam. Ask for custom plugs or noise-canceling earmuffs with communication.

- Insist on training. Don’t just watch a video - ask for hands-on help inserting your earplugs.

- Get your annual hearing test. Even if you think your hearing is fine. NIHL starts subtly.

- Report unsafe noise levels. If you’re near a machine and have to yell to talk to someone next to you, it’s too loud.

- Use your ears as a tool. If your ears ring after work, that’s a warning sign. Don’t ignore it.

If you manage a team:

- Measure your noise levels. Don’t guess.

- Invest in quieter tools. The ‘Buy-Quiet’ database is free.

- Make hearing protection part of your safety culture - not an afterthought.

- Track compliance. Don’t just hand out earplugs. Check if they’re being used correctly.

Is There Hope for the Future?

Yes. New tech is helping. Smart earplugs like 3M’s PELTOR TS3+ now record your daily noise exposure and send alerts if you’re over the limit. Researchers are testing blood biomarkers to detect early hearing damage before it shows up on an audiogram.

But technology alone won’t fix this. The real solution is culture. Companies that treat hearing protection like safety gear - like hard hats and gloves - see the best results. Workers who feel heard, who see management taking action, are more likely to protect themselves.

NIHL is 100% preventable. But only if we stop treating it like an inevitable part of the job. It’s not. It’s a failure of systems - not of workers.

Can noise-induced hearing loss be reversed?

No. Once the hair cells in your inner ear are damaged by loud noise, they don’t regenerate. The hearing loss is permanent. That’s why prevention is the only effective strategy. You can’t undo the damage - but you can stop it from getting worse.

Are earplugs enough to protect my hearing?

Not on their own. Earplugs are the last line of defense. If noise levels are above 90 dBA, engineering controls like enclosures or quieter equipment must be used first. Even the best earplugs only work if worn correctly and consistently. Studies show most workers insert foam plugs wrong, cutting protection in half.

What’s the difference between OSHA and NIOSH noise limits?

OSHA allows 90 dBA for 8 hours with a 5-dB exchange rate - meaning exposure time halves every 5 dB increase. NIOSH recommends 85 dBA with a 3-dB exchange rate, which is far more protective. At 95 dBA, OSHA allows 4 hours, but NIOSH allows just 1 hour. The difference means NIOSH’s limit reduces noise energy exposure by 16 times more than OSHA’s.

How do I know if my workplace is too noisy?

If you have to shout to talk to someone an arm’s length away, the noise is likely above 85 dBA. You can also use a smartphone app like NIOSH’s Sound Level Meter (free for iOS) for a rough estimate. But for accurate readings, a calibrated Type 2 sound meter is required by law for compliance testing.

Can I get my hearing tested for free at work?

Yes - if you work in a job with noise levels at or above 85 dBA, your employer is legally required to provide annual hearing tests at no cost to you. These tests are done by a licensed audiologist and track changes over time. Don’t skip them - early detection is your best defense.

Andrew Baggley

November 20, 2025 AT 18:38Zac Gray

November 20, 2025 AT 23:52Michael Salmon

November 22, 2025 AT 05:50Christopher K

November 23, 2025 AT 23:11Christopher Robinson

November 25, 2025 AT 13:11James Ó Nuanáin

November 27, 2025 AT 05:21Kara Binning

November 27, 2025 AT 17:02river weiss

November 29, 2025 AT 01:53seamus moginie

November 30, 2025 AT 05:49Dana Dolan

December 1, 2025 AT 21:48Steve and Charlie Maidment

December 2, 2025 AT 22:46Michael Petesch

December 4, 2025 AT 22:16Ellen Calnan

December 6, 2025 AT 09:15Richard Risemberg

December 7, 2025 AT 05:22